each global marine engine type and recently, we have been manufacturing

HP SCR Chambers and EGR Units, the nitrogen oxide reduction devices,

in compliance with the Tier III regulations proposed by IMO.

In particular, we mainly produce large engines and handle all processes

in-house, from cutting raw materials to welding, machining, painting, and

insulation, to produce the best products.

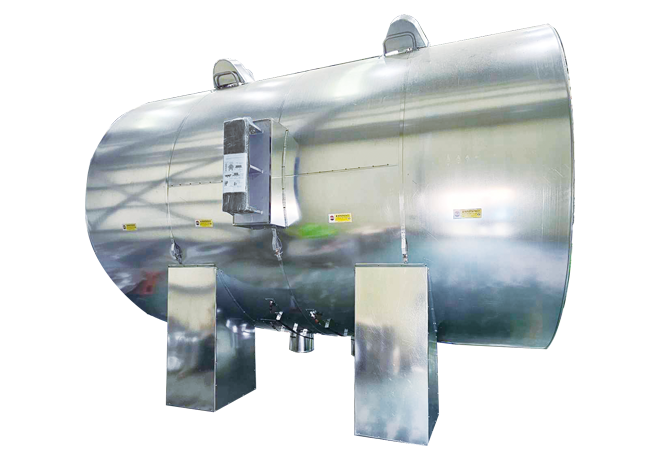

It is a storage tank for compressed air for combustion, and serves to store

the compressed air needed to run the ship's engine.

Generally, in diesel engines, compressed air is injected into the combustion

chamber to burn fuel, and in large marine engines, it is essential for the

primary function of distributing and supplying compressed air to each

combustion chamber for combustion.

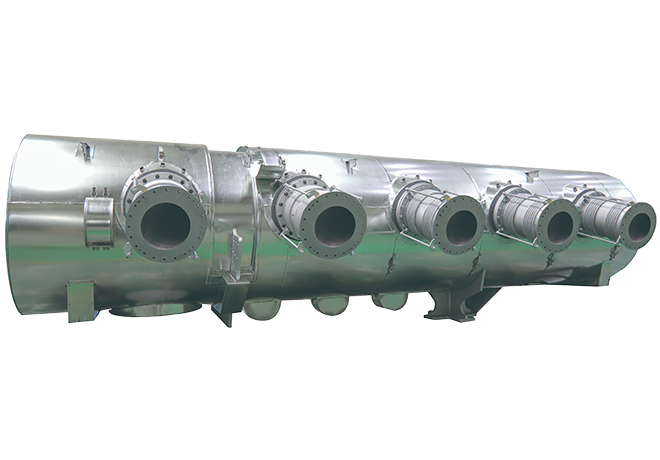

It collects and stores the high-temperature, high-pressure exhaust

combusted in each cylinder and delivers it to the turbocharger.

It contributes to the effective handling of high-temperature, high-pressure

exhaust gases and the optimization of engine performance.

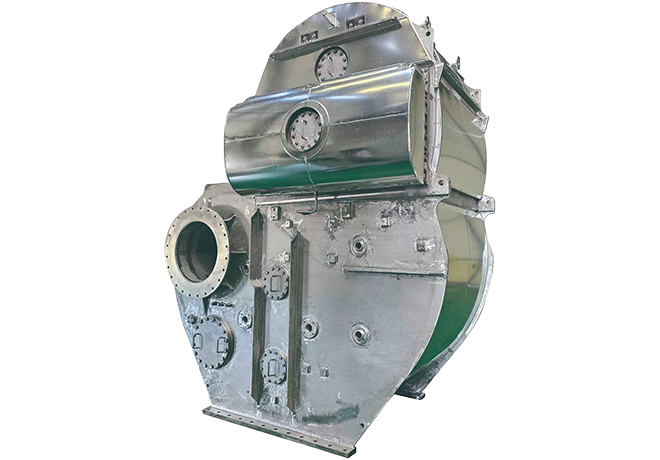

It is an exhaust aftertreatment device that utilizes a selective reduction

catalyst to effectively reduce nitrogen oxides emitted by the engine.

It reduces nitrogen oxides in the engine exhaust by converting it to harmless

nitrogen (N2) and water (H2O) using a reducing agent. This device is essential

for compliance with Tier III regulations set by the International Maritime

Organization (IMO).

It is a device for effectively reducing nitrogen oxides produced during fuel

combustion through exhaust gas recirculation.

To reduce nitrogen oxides produced during the fuel combustion, it circulates

a portion of the exhaust back into the intake system to reduce nitrogen

oxides produced during the combustion process. This device is essential for

compliance with Tier III regulations set by the International Maritime

Organization (IMO).